The race to Mars quietly enjoyed two giant leaps toward reality in recent months. A journey to the red planet poses many challenges: propulsion, radiation shielding, predicting what a ship and crew would need to make the journey, and of course, human health over the 500+ theoretical mission days.

Addressing the health piece, NASA Astronaut Scott Kelly and RFSA Cosmonaut Mikhail Kornienko will spend an entire year in orbit, a long-duration experiment designed to study physiological changes in weightlessness, as well as psychological reactions to isolation.

The other piece? A small company called Made In Space announced that an astronaut on the International Space Station installed their 3D printer inside the Micro-Gravity Science GloveBox, created the first test print in orbit, then further printed a custom tool for a repair. Before the printer was there, Barry "Butch" Wilmore would have had to wait for the right tool to be delivered on the next rocket from Earth!

The ratchet heard 'round the world

Many moons ago, I wrote a blog article entitled "Regolith Castles" (March 2011) wherein I detailed the adventures of Enrico Dini, who used lunar analog material to make giant 3D prints (or, layered composites based on 3D software models) of structures that might one day be used to build habitats in low gravity on our Moon.

3D printers were invented in the 1980s, but it took until the 2000s for them to show up in TED talks and seminars about new "disruptive technologies" of the 21st century. Also now known as "additive manufacturing," 3D printing has now made splashes in many supply industries (from metals to chocolate!) and was even featured on The Big Bang Theory in January of 2013. Can a reality TV show be far behind??

If anyone had asked me "How long until we have a 3D printer that can operate in micro-gravity?" I'm quite sure my answer would have been, "It won't be on this current space station. It will be on the next one after 2030." Then, perhaps, Enrico Dini's visions in the next decade. But, the leap came earlier than expected!

Made In Space has completed 20+ 3D prints in orbit since the first test print in November of 2014, and will compare the items made in micro-gravity to those made on Earth.

3-D printers on the ground? New. Cool. Fun! 3D printer in space?? This doesn't just change the game. It changes the entire sport. Imagine basically emailing new items into space instead of launching them inside rockets.

As with most spacetweeps, the first thing that popped into my head was Apollo 13. With the ability to send software to a spacecraft, and print whatever parts are needed, the practical applications are at once obvious -- and mind-blowing.

Launching heavy hardware is expensive. Any spacecraft can now potentially take printers and lighter raw materials, to create customized tools with reduced human effort. When there's no making a quick U-turn back to Earth in dire emergencies, a machine that can swiftly print what is needed, on demand, from a medical cast for a broken wrist to new receptacles for the inevitable hydroponics farms, the 3D printer becomes the new "Spacecraft Must Have."

The technology will extend to food such as 3D printed pizza, accessories such as 3D printed cameras, and eventually, perhaps even metals for hull or hatch repairs, or fabrics for spacesuit patches. One thing is certain: in the not-far-future, probably closer than we think, there will be no such thing as a mission without multiple additive manufacturing printers.

3D printers will be the new way we build things in space: satellites, space stations, spacecraft internal quarters, and ultimately, off-world colony habitats. No more lugging along millions of dollars worth of spare parts that must be stored, but may never be used.

Second Printer: The AMF

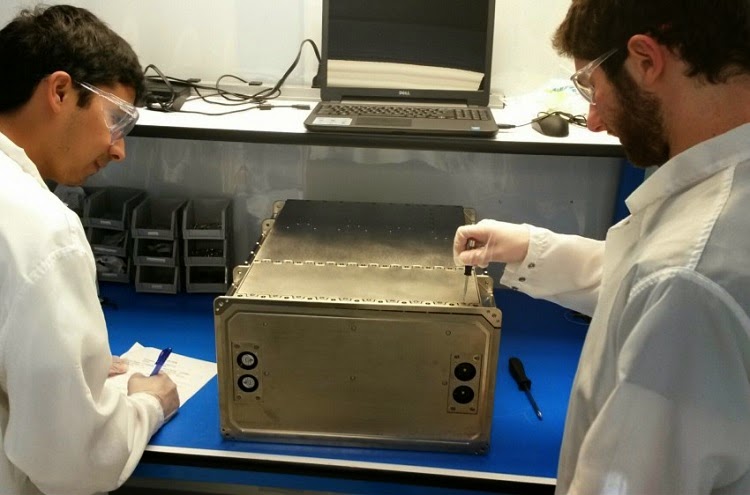

Photo courtesy of Made In Space, Inc.

Photo courtesy of Made In Space, Inc.

Made In Space will be launching it's second printer in 2015, the AMF, or "Additive Manufacturing Facility." NASA will still be a customer, but in addition to their continued experiments with station supplies, this larger and higher-precision hardware will be made commercially available to companies, universities, government agencies, and artists who are interested in the ability to create objects in space.